- Products List

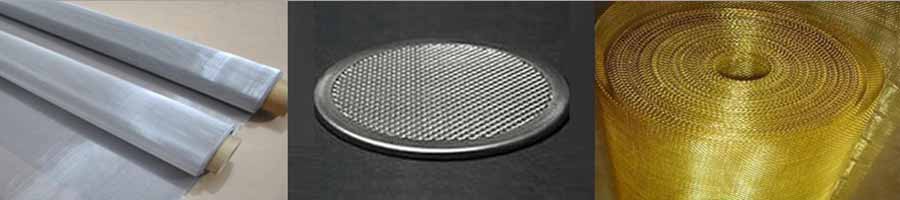

Stainless Steel Wire Mesh

4 Mesh Stainless Steel Wire Mesh

10 Mesh Stainless Steel Wire Mesh

20 Mesh Stainless Steel Wire Mesh

30 Mesh Stainless Steel Wire Mesh

40 Mesh Stainless Steel Wire Mesh

50 Mesh Stainless Steel Wire Mesh

60 Mesh Stainless Steel Wire Mesh

80 Mesh Stainless Steel Wire Mesh

100 Mesh Stainless Steel Wire Mesh

120 Mesh Stainless Steel Wire Mesh

150 Mesh Stainless Steel Wire Mesh

200 Mesh Stainless Steel Wire Mesh

300 Mesh Stainless Steel Wire Mesh

325 Mesh Stainless Steel Wire Mesh

400 Mesh Stainless Steel Wire Mesh

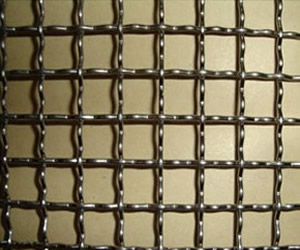

Pre-crimped Wire Mesh

Stainless Steel Security Screen

Stainless Steel Wire

Filter Disc

Stainless Steel Filter Element

Stainless Steel Pleated Filter Element

Stainless Steel Barbecue Grill Mesh

Brass Wire Mesh

80 Mesh Brass Wire Mesh

100 Mesh Brass Wire Mesh

120 Mesh Brass Wire Mesh

150 Mesh Brass Wire Mesh

Welded Mesh Panel Machine

Welded mesh panel machine adopts late-model high efficient welding transformer. The voltage adjusting range is big and it can fall into eight different grades, which enlarge the range of wire diameter size. In order to adapt the capacity of the clients’ main power transformer and reduce the rush of the current, electric and electronic welding control adopt the separating control electricity input, i.e., the welding transformers don’t work at the same time but in several times when welding the same row of cross wires.

Electric and electronic welding control system adopts synchronous control technology. The welding time and separating control welding is composed of numeric integrated circuit, which is with high control precision and stable function. The mesh pulling system is controlled by step motor, which makes the pulling aperture more standard and accurate.

The line wire and the cross wire are pre-straightened and cut.

The mesh aperture size welded is diversified. The line wire spacing can be adjusted through the related parts. The cross wire spacing adjusting is controlled by microcomputer. It can exist different cross distances on one piece of mesh sheet.

welded mesh panel machine can be used to produce mine timbering mesh panel, railway fence mesh panel, express highway fence mesh panel, high building mesh panel and flower room mesh panel .

Main parameter :

| Input power | 380v 50hz | Welding point No. | 13 |

| Max. mesh width | 1200mm | Feed line wire | Pre-straightened and cut |

| Line wire space | 100-200mm | Feed cross wire | Pre-straightened and cut |

| Cross wire space | 100-200mm | Motor power | 4.0KW |

| Line wire diameter | 3.0-6.0mm | Welding speed | 45times/min |

| Cross wire diameter | 3.0-6.0mm | weight | 2700kg |

| Welding transformer | 120KVA*2 | Overall dimension | 1900*5500*1300mm |

Stainless Filter Element

Stainless Filter Element Stainless Wire Mesh

Stainless Wire Mesh Brass Wire Mesh

Brass Wire Mesh Mesh Pleated Filter

Mesh Pleated Filter Filter Disc

Filter Disc Barbecue Grill Mesh

Barbecue Grill Mesh Crimped Wire Mesh

Crimped Wire Mesh Stainless Steel Wire

Stainless Steel Wire Security Screen

Security Screen